Jobs in Abuja FCT

Jobs in Rivers State

Jobs in Oyo State

Jobs in Enugu State

Jobs in Edo State

Jobs in Kaduna State

Click here to see more states

Jobs in Abuja FCT

Jobs in Adamawa State

Jobs in Akwa Ibom State

Jobs in Anambra State

Jobs in Bauchi State

Jobs in Bayelsa State

Jobs in Benue State

Jobs in Borno State

Jobs in Cross-River State

Jobs in Delta State

Jobs in Ebonyi State

Jobs in Edo State

Jobs in Ekiti State

Jobs in Enugu State

Jobs in Gombe State

Jobs in Imo State

Jobs in jigawa State

Jobs in Kaduna State

Jobs in Kano State

Jobs in Katsina State

Jobs in Kebbi State

Jobs in Kogi State

Jobs in Kwara State

Jobs in Lagos State

Jobs in Nassarawa State

Jobs in Niger State

Jobs in Ogun State

Jobs in Ondo State

Jobs in Osun State

Jobs in Oyo State

Jobs in Plateau State

Jobs in Rivers State

Jobs in Sokoto State

Jobs in Taraba State

Jobs in Yobe State

Jobs in Zamfara State

SSCE/GCE/NECO Jobs

OND/NCE Jobs in Nigeria

HND Jobs in Nigeria

BSc/BA/BEng Jobs

LL.B/BL Jobs in Nigeria

B.Pharm Jobs in Nigeria

MBBS/MBBCh Jobs

MSc/MA Jobs in Nigeria

PhD Jobs in Nigeria

Administrative Jobs in Nigeria

Advertising Jobs Nigeria

Accounting Jobs in Nigeria

Auditing Jobs Nigeria

Arts Jobs in Nigeria

Android / IOS Developer Jobs

Agriculture Jobs in Nigeria

Architecture Jobs in Nigeria

Aviation Jobs in Nigeria

Automobile Jobs in Nigeria

Banking Jobs in Nigeria

Computer & InfoTech Jobs

Computer / IT Support Jobs

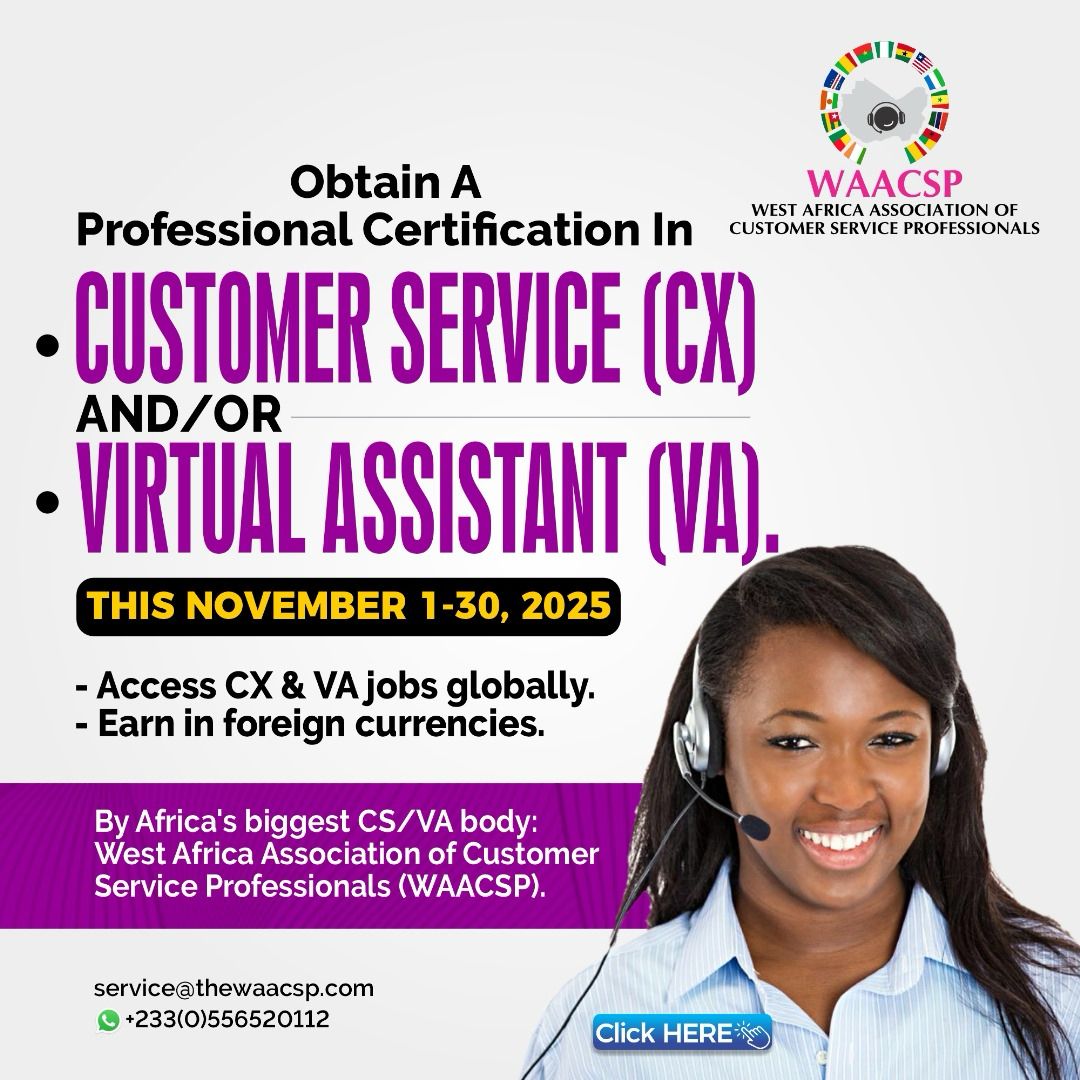

Customer Service Jobs

Civil Engineering Jobs

Cook / Chef Jobs

Database Jobs in Nigeria

Driving / Dispatch Rider Jobs

Education Jobs for Nigerians

Real Estate Jobs

Electrical/Electronics Jobs

Engineering Jobs in Nigeria

Facility Mgt Jobs in Nigeria

Finance Jobs in Nigeria

Front Desk Jobs in Nigeria

Geology Jobs

Government Jobs in Nigeria-

Graphics Design Jobs

Hospitality Jobs in Nigeria

Hotel Jobs in Nigeria

HR Jobs in Nigeria

Industrial Attachment (Internship)

Insurance Jobs in Nigeria

Journalism / Content Writing Jobs

Law Enforcement / Security Jobs

Lecturing Jobs in Nigeria

Law / Legal Jobs in Nigeria

Linux & Unix Jobs Nigeria

Marketing & Sales Jobs

Maritime & Shipping Jobs

Medical & Healthcare Jobs

Military Jobs in Nigeria

Computer Networking Jobs

NGO Jobs in Nigeria

Oil & Gas Jobs in Nigeria

Oracle Jobs in Nigeria

Personal Assistant Jobs

PHP & MySQL Jobs in Nigeria

Physician / Medical Officer Jobs

Public Relation Jobs

Programming / Software Jobs

Pri/Sec Sch Teaching Jobs

Real Estate Jobs in Nigeria

Remote / Work-at-home Jobs

Research Jobs in Nigeria

Safety & Health Jobs

Secretarial Jobs in Nigeria

Security Jobs in Nigeria

Sales Jobs

Shipping & Maritime Jobs

Student Jobs in Nigeria

Software Developer Jobs

System Admin Jobs in Nigeria

Teaching Jobs in Nigeria

Telecommunication Jobs

Semi-skilled / Factory Work

Volunteer Jobs Nigeria

Web Developer Jobs Nigeria

Web Designer / Frontend / UI Jobs

Nautilus Nigeria Engineering and Construction Limited (NNEC) Job Recruitment (9 Positions)

Biufort Homes Limited Job Recruitment (3 Positions)

Pruvia Integrated Limited (PIL) Job Recruitment (13 Positions)

Radmosa Edu Job Recruitment (9 Positions)

Century 21 System Communications Limited Job Recruitment (3 Positions)

DOAH Enterprise Job Recruitment (3 Positions)

Powerchina Huadong Nigeria Limited Trainee and Exp. Job Recruitment (4 Positions)

Flutterwave Job Recruitment (3 Positions)

The Change Room Job Recruitment (7 Positions)

Kyosk Digital Services Limited Job Recruitment (4 Positions)

Vopnucity Nigeria Limited Job Recruitment (7 Positions)

Coca-Cola Company Job Recruitment

ShogxyPro Outsourcing Job Recruitment (4 Positions)

Harobed & Associates (H&A) Limited Job Recruitment (3 Positions)

Infytel Communications Limited Job Recruitment (6 Positions)

Bilaad Realty Limited Job Recruitment (3 Positions)

Ernst & Young (EY) Job Recruitment

Odixcity Consulting Job Recruitment (5 Positions)

Karis Concept Job Recruitment (6 Positions)

Kanselor Business Innovation Campus Limited Job Recruitment (3 Positions)

Pitstop Lagos Job Recruitment (3 Positions)

Ascentech Services Limited Job Recruitment (52 Positions)

Majeurs Holdings Limited Job Recruitment (5 Positions)

Teach For All Job Recruitment (3 Positions)

First Bank of Nigeria Limited (FirstBank) Job Recruitment (12 Positions)

Zico Petroleum and Marketing Company Limited (ZPMCL Job Recruitment (3 Positions)

Premierhub Innovation Center Job Recruitment (3 Positions)

AB Microfinance Bank Nigeria Job Recruitment (4 Positions)

Enoella Consult Graduate & Exp. Job Recruitment (8 Positions)

Voltaire Lifestyle Services Limited Job Recruitment (8 Positions)

Anheuser-Busch InBev (AB InBev) Job Recruitment

Bolton White Group Job Recruitment (4 Positions)

ADDAS Ultimate Limited Job Recruitment (4 Positions)

Interswitch Group Job Recruitment (5 Positions)

Greenlands Academy Job Recruitment (9 Positions)

Lacare Staffing Solutions Job Recruitment (4 Positions)

MOC Consulting Limited Job Recruitment (3 Positions)

Naji Realties Internship & Exp. Job Recruitment (3 Positions)

Alan & Grant Job Recruitment (12 Positions)

Reputable Pharmaceutical Company Job Recruitment (5 Positions)

ICS Outsourcing Limited Job Recruitment (10 Positions)

Brit Properties Job Recruitment (4 Positions)

Kiyix Recruitment Hub Job Recruitment (7 Positions)

Brands and Trade Limited Job Recruitment (4 Positions)

AMO-HR Solutions Job Recruitment (5 Positions)

Risingstar Recruitment Job Recruitment (3 Positions)

Fort Knox Outsourcing Job Recruitment (39 Positions)

Beacongate Limited Job Recruitment (6 Positions)

eHealth4everyone Job Recruitment (6 Positions)

Instrument Technician 3 at BGI Energy Services Limited

Posted on Wed 29th Oct, 2025 - hotnigerianjobs.com --- (0 comments)BGI Energy Services Limited is an Indigenous engineering, procurement, construction, maintenance and asset integrity management company operating in the Nigerian oil and gas industry with essential local participation and increased local content.

We are recruiting to fill the position below:

Job Title: Instrument Technician 3

Location: Warri Delta

Employment Type: Contract

Project Overview

- The Instrument Technician will be responsible for the installation, calibration, maintenance, and troubleshooting of instrumentation and control systems at the EGTL refining and utilities plant units located in Escravos, Delta.

- The technician will ensure optimal performance of process control systems to maintain safe, efficient, and reliable plant operations.

Objectives:

- Ensure continuous Maintenance, reliability and safe operation of instrumentation systems in EGTL utilities plant and Product work up units.

- Minimize downtime through proactive maintenance and timely troubleshooting.

- Support plant operations by maintaining accurate and reliable measurement and control systems.

- Comply with all safety, environmental, and regulatory standards.

Scope of Services

Installation & Commissioning:

- nstall, configure, and commission field instrumentation including pressure, temperature, flow, and level transmitters.

- Install and calibrate control valves, actuators, and positioners.Assist in loop checking and functional testing of control systems during commissioning.

- Interpret and implement instrument loop diagrams, P&IDs, and wiring schematics.Maintenance & CalibrationPerform preventive, corrective, and predictive maintenance on instrumentation and control systems.

- Calibrate instruments using standard calibration equipment and procedures.

- Maintain calibration records and ensure compliance with ISO and plant standards.Replace faulty components and ensure minimal disruption to operations.

- Troubleshooting & RepairsDiagnose faults in instrumentation systems including PLCs, DCS, SCADA, and field devices.

- Repair or replace defective components and ensure proper functionality.

- Collaborate with electrical and mechanical teams to resolve cross-disciplinary issues.

Documentation & Reporting:

- Maintain accurate records of maintenance activities, calibration certificates, and equipment history.

- Update instrument databases and asset management systems.

- Prepare technical reports and contribute to root cause analysis for equipment failures.

Compliance & Safety:

- Adhere to all site safety protocols and procedures.

- Ensure compliance with local and international standards (e.g., IEC, ISA, API).

- Participate in safety audits, toolbox talks, and risk assessments.

Continuous Improvement:

- Recommend upgrades or replacements for obsolete or underperforming instruments.

- Participate in reliability improvement initiatives.

- Support training and mentoring of junior technicians.

Deliverables:

- Fully functional and calibrated instrumentation systems.

- Maintenance and calibration logs.

- Fault diagnosis and resolution reports.

- Updated documentation (P&IDs, loop drawings, instrument index).

- Compliance with safety and environmental regulations.

Duration:

- Initial contract duration: 12 months, renewable based on performance and project needs.

- Work schedule: Rotational shift (e.g., 14/14 or 21/7) depending on operational requirements.

Technical Skills:

- Proficiency in calibration and maintenance of field instruments (pressure, temperature, flow, level).

- Knowledge of PLCs, DCS, SCADA systems (e.g., Siemens, ABB, Honeywell, Yokogawa).

- Have experience with ERP systems (e.g., JDE, SAP and SMART by GEP)

- Familiarity with control valve operations and configurations.

- Ability to read and interpret technical drawings and documentation.

Soft Skills:

- Strong analytical and problem-solving skills.

- Effective communication and teamwork abilities.

- Attention to detail and commitment to safety.

Educational Requirements

- National Diploma (ND), Higher National Diploma (HND), or bachelor’s degree in Instrumentation Engineering, Electrical/Electronics Engineering, or related field.

Relevant Experience:

- Minimum 5 years of hands-on experience in instrumentation within oil & gas, petrochemical, or utility plants.

- Experience in hazardous area instrumentation and ATEX-rated equipment.

- Proven track record in preventive and corrective maintenance programs.

Compulsory:

- Instrumentation Certification (e.g., ISA Certified Control Systems Technician – CCST).

- HSE Certification (e.g., NEBOSH, OSHA).

- Valid Offshore Survival Certificate (BOSIET or HUET).

- Electrical Safety Certification.

Preferred:

- Vendor-specific training (e.g., Siemens, Emerson, Yokogawa).

- Calibration and Metrology Certification.

- Confined Space Entry and Working at Heights Certification.

Tools & Equipment:

- Calibration tools (e.g., HART Communicator, multifunction calibrators).

- Multimeter, loop calibrators, pressure gauges.

- Laptop with relevant software (e.g., PLC programming tools, DCS configuration software).

- PPE as per site safety standards.

Performance Metrics:

- Equipment uptime and reliability.

- Response time to faults and breakdowns.

- Compliance with maintenance schedules.

- Safety performance and incident-free operations.

- Quality of documentation and reporting.

Application Closing Date

2nd November, 2025.

How to Apply

Interested and qualified candidates should send their cover letter and CV to: bgirecruitment2@gmail.com using the job title as the subject of the mail.

University of Uyo (UNIUYO) Massive Graduate and Exp. Academic and Non-Academic Job Recruitment (49 Positions)

Southwestern University Nigeria Massive Academic and Non-Academic Job Recruitment (88 Positions)

University of Ibadan (UI) Massive Academic and Non-academic Job Recruitment (372 Positions)

Federal University Oye-Ekiti (FUOYE) Massive Graduate and Exp. Academic and Non-Academic Job Recruitment (384 Positions)

Nigerian Air Force List of Successful Candidates for Direct Short Service Commission Course (DSSC) 34 / 2025 Zonal General Aptitude Test

Access Bank Plc Entry Level & Exp. Job Recruitment (5 Positions)

MTN Global Graduate Development Programme - Nigeria 2026

Dangote Cement Management Trainee Programme 2025

Nigerian Air Force (NAF) Basic Military Training Course 46 / 2025 (Airmen and Airwomen) - 38 Positions

Access Bank Plc Entry Level Training Program 2025

Ecobank Nigeria Entry Level Development Programme (ELDP) 2025

Nigerian Navy Basic Training School (NNBTS) Job Recruitment (45 Positions)

FSDH Merchant Bank Limited Management Associate (MA) Program 2025

Management Trainee at Reckitt Benckiser Group Plc